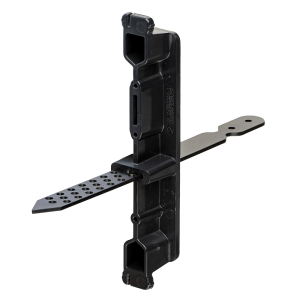

Fiberglass Pool Clip

Assess the shape of the pool and determine whether you will need to bend the coping around corners or create 90° corners.

a) Bending the coping

b) Creating 90° corners

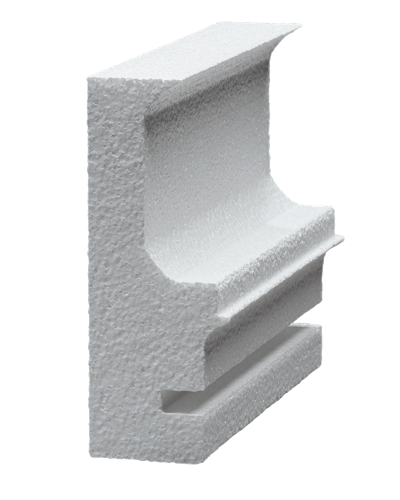

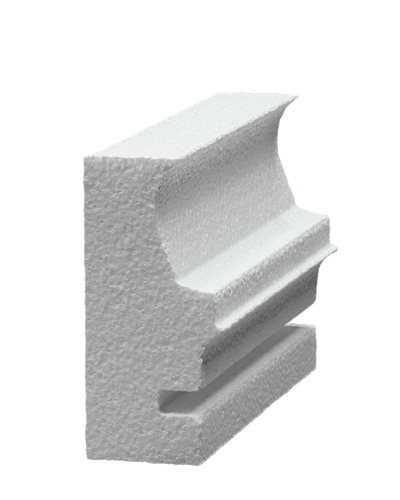

Fasten the coping to the pool using either the Fiberglass clip or the Universal clip, depending on the type of pool installation:

i) Insert the clips into the form, using the perforated slots on the back of the profile. For best results, clips should be 10-12" apart around the curves and 8-10" apart where the pool is straight.

ii) Position the form, then push tight on the clip and form to make sure there aren't any gaps. Using a 1' self-tapping screw, fasten the clip to the fiberglass pool. NOTE: The form is designed to cradle the top of a fiberglass pool, eliminating the need for a plumb strip.

Ready to pour! Remember to spray the forms with form release or cooking oil and remove all bending tape prior to pouring. You can also insert wooden skewers into the joints for added support.

Pour the concrete away from the coping and rake or shovel it into the coping form. Using a vibrating tool, vibrate around the coping for a smooth finish.

Stripping the forms. Before the concrete has fully cured, break off the clips by rotating a quarter turn and slowly remove the coping forms. Using a damp sponge or paint brush, smooth out the joints and edges.

Removing the Tabs

Using the slide hammer tool, clamp onto the remaining tab and pull away on a downward angle using force to remove the tab. Make sure to save some cement to fill the voids and touch up the profile.